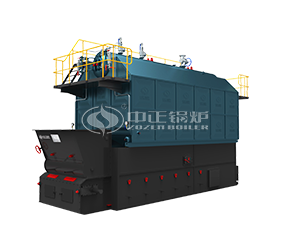

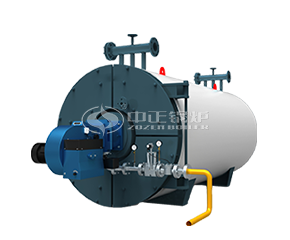

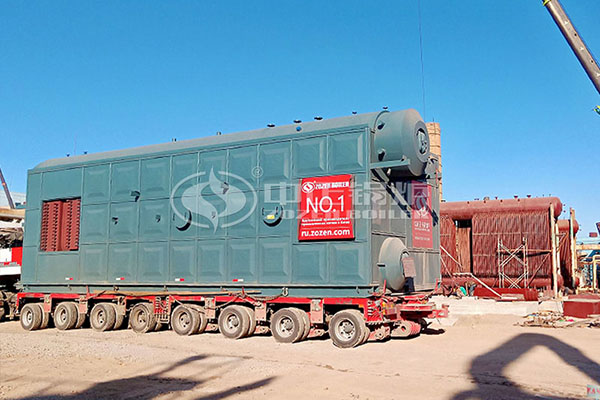

Boiler for the textile industry

Textile refers to a multi-scale structural processing technique of a fiber or fiber assembly, it includes many steam consuming sections including dyeing, drying, slashing, printing, pressing etc.., all of which needs steam from boilers. With the increase in the demand for textiles, the steam consumption of textile factories is also increasing. Whether building a new textile factory or rebuilding and expanding a textile factory are faced with the problem of boiler selection.