Overview

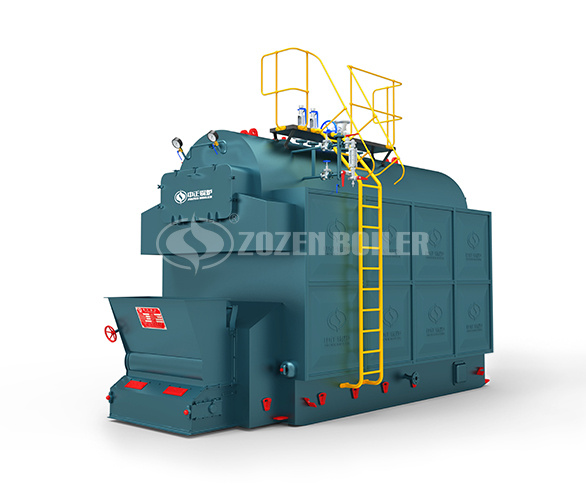

The main processes of the paper industry are: pulping, pressing, drying, calendering, winding, rewinding, warehousing, etc. The pulping methods mainly include mechanical pulping, chemical pulping, semi-chemical pulping and bio-pulping. In the paper production, the heating and dissolving, machine shaping, Black slurry concentration and Squeeze drying of the chemicals in the pulping process all require heat sources, so the boiler is the main driving force for the production of the paper mill. The boiler uses coal or other fuels to generate high-temperature heat sources through conversion energy, and we transport the heat sources to various workshops for steaming and drying purposes. Because the production process consumes more energy in the production process of the paper mill, the energy cost can account for 10%-14% of the production cost. Therefore, energy conservation and consumption reduction has become one of the main ways for papermaking enterprises to increase production and save energy, improve economic efficiency and enhance competition in the product market.