Case introduction

Industrial boilers have been widely used in the chemical industry all the time. They play an indispensable role in the pretreatment, hydrogenation, decomposition, and distillation of oleochemicals. Hangzhou Oleochemicals Co., Ltd. was founded in 1973 (the predecessor was Hangzhou Grease Chemical Factory) is a state-owned enterprise which was invested and built by the former Ministry of Light Industry of China. The enterprise was restructured in 2000 and it is now a wholly-owned subsidiary of Zhejiang Zanyu Technology Group Co., Ltd. that has formed a style of simultaneous development of multiple products series. It supplies significant raw materials for manufacturing industries in food, chemicals, plastic, rubber, cosmetics, flavor and fragrance fields and deeply win trusts from many customers at home and abroad.

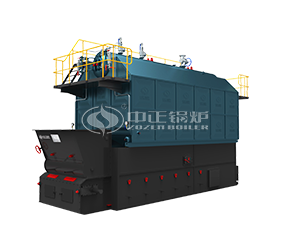

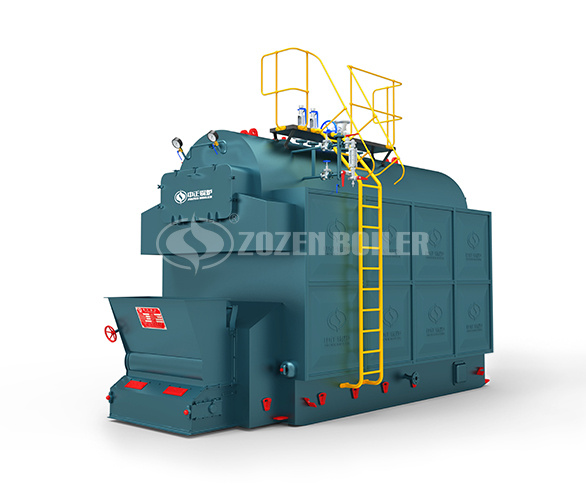

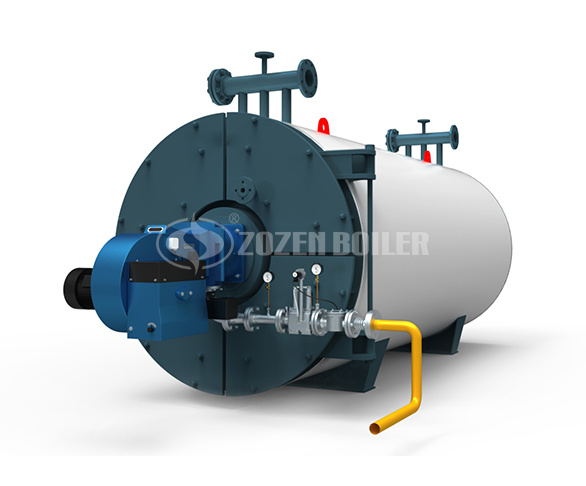

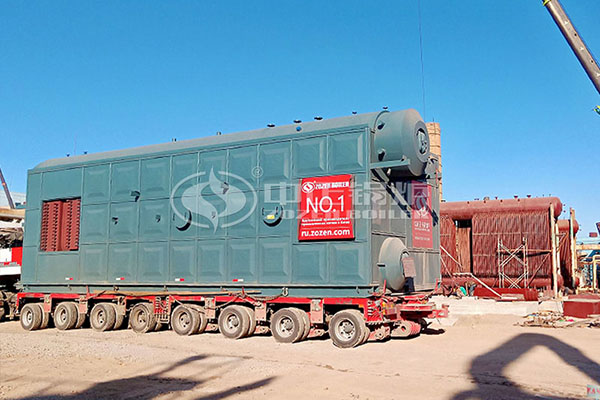

Indonesia is an important exporter of oleochemical raw materials. Hangzhou Oleochemicals Co., Ltd. locally acquired PT. DUA KUDA INDONESIA, modifying, and expanding production lines, introducing the DHL series field-erected coal-fired boiler produced by ZOZEN boiler. The drum of this series is external style, which has the advantages of corner tube boiler: compact structure, low steel consumption and fast temperature rising, etc. The DHL series coal-fired boiler is a front and back arch covered furnace structure. A refractory concrete front arch is built on the lower section of the front wall of the furnace as a fire arch, and the rear arch is a ignition arch. Meanwhile, the isobaric system warehouse air supply, the micro area adjustment of the air distribution and wide coal furnace arch design further improve the combustion efficiency and furnace temperature. Additionally, the membrane water wall with fully sealed structure are used around the boiler body and the middle partition wall to ensure that the boiler thermal efficiency reaches higher than 82%.