Case introduction

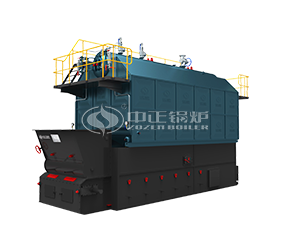

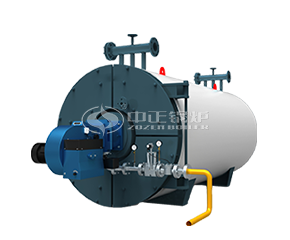

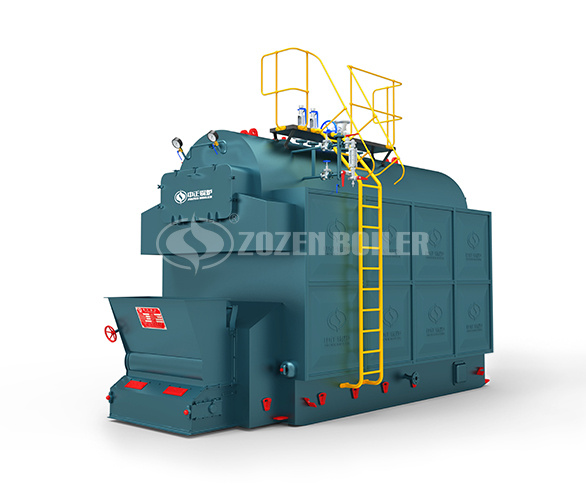

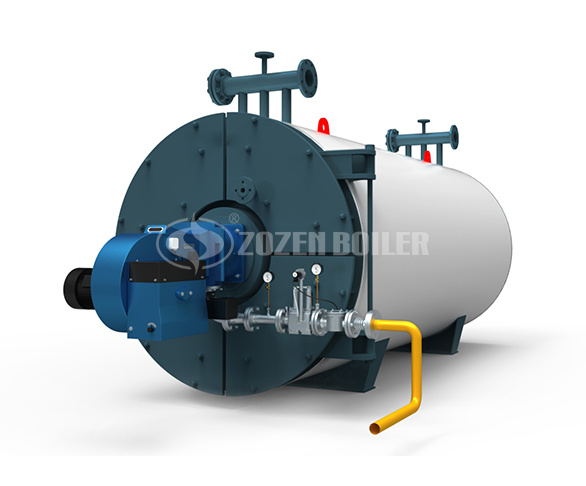

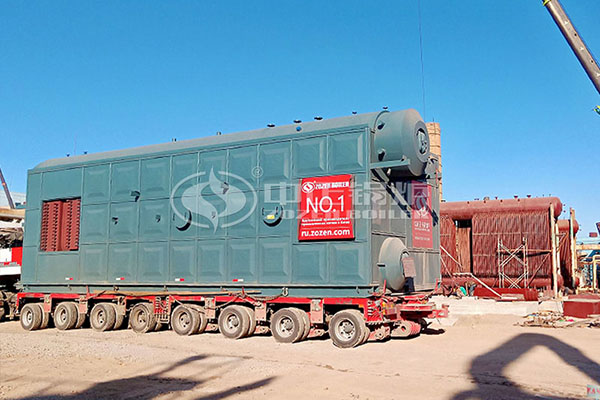

In the process of tire manufacturing, rubber mixing and vulcanization are two indispensable processes. Many tire factories generally build or use heating boilers of other companies in order to provide high-temperature steam for tire vulcanization. so as to meet the needs of production, Sentury Tire (Thailand) Co., Ltd. believes that the SZL series biomass-fired boilers of ZOZEN boiler are superior to those of other companies in terms of fuel efficiency and energy saving. At the same time, the ZOZEN technical team also designed speed control box with a reasonable speed according to the burning rate, and established different numbers of independent wind bins according to different tonnages to ensure that the fuel is fully burned. In the end, Sentury Tire (Thailand) Co., Ltd. purchased 2 sets of 20 tph biomass-fired steam boilers at ZOZEN.