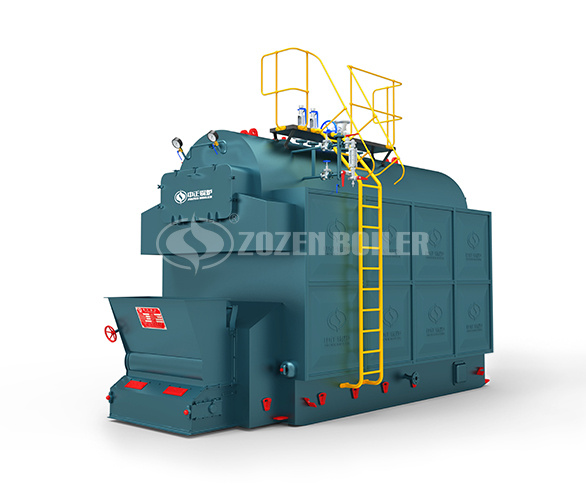

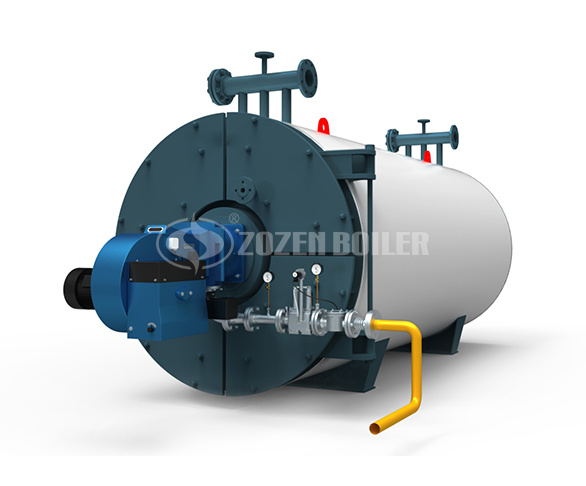

In gas-fired steam boiler equipment, the amount of water is very considerable, and a ton of gas-fired steam boiler uses about 1.1 tons of water per hour. This shows the influence of water quality on boilers. So, how do we ensure good water quality when using gas-fired steam boilers? Let ZOZEN Boiler tell you the answer.

Gas-fired steam boiler is an indispensable equipment in the production process of steam boilers of major manufacturers, and it is also one of the more common types of steam boilers. Among them, water quality has a relatively large impact on its normal operation, which in turn affects the production efficiency of enterprises. Among them, the more significant impact on the company's water is the suspended matter and dissolved matter in the boiler water. If it is not treated in time, it will easily cause a certain impact on the safety of the boiler operation. For example, dissolved substances, calcium and magnesium salts, are one of the important causes of fouling in steam boilers. Long-term fouling of the boiler will cause the heat transfer effect of the boiler to be reduced, the operating efficiency of the boiler is low, and it can cause boiler accidents in serious cases. Therefore, the steam boiler of the textile factory should pay special attention to this point in the process of use. In addition, things like suspended matter will directly affect the quality of the water, reduce the quality of the boiler, and even cause problems such as blockage of the boiler pipes that damage the boiler components. Therefore, the boiler must pay attention to water treatment during the operation of the boiler, and select appropriate treatment equipment and procedures in strict accordance with the treatment regulations to reduce unnecessary boiler losses and extend the service life of the boiler.

During the operation of the gas-fired steam boiler, the phenomenon of steam carrying water is easy to occur, but this is actually another solution.

(1) Boiler water must be inspected and meet national regulations before it can be supplied to boilers.

(2) When the boiler is running, it is necessary to ensure that the boiler water is at a normal water level to avoid excessively high boiler water level to reduce steam space, and then the phenomenon of steam with water.

(3) If the steam boiler is running due to the large gas volume, the water-carrying phenomenon may be more serious. This may be due to the unreasonable design of the size of the air bag, the water level can be appropriately reduced, and the steam space can be increased to avoid the phenomenon of steam carrying water during operation. If the boiler steam is carrying water more severely, it may cause the boiler steam humidity to exceed the controllable range, which will cause inconvenience to users and affect the operating life of the boiler itself. Therefore, when using the steam boiler, you should take measures based on actual conditions. Corresponding measures are taken to avoid such phenomena and ensure the safe and efficient operation of boilers.