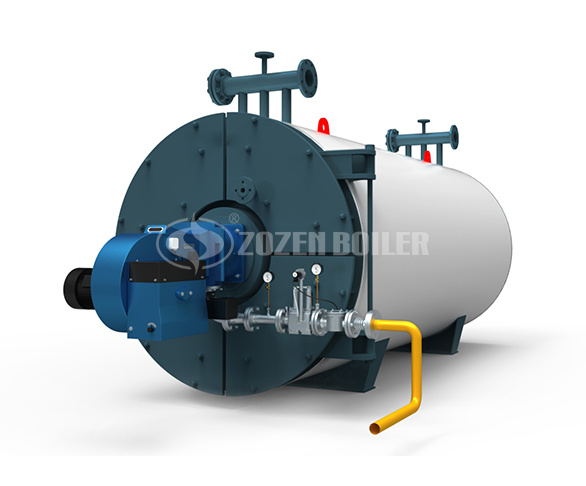

Most food factories choose to use steam boilers to disinfect and sterilize food through high-temperature steam output from the boiler. Due to the importance of the food industry to human health, the requirements for steam boilers are also very high. If the user finds that there is water in the boiler when operating the boiler, how to deal with it in time? Let ZOZEN Boiler tell you the answer.

1. Boiler water must be inspected and meet national regulations before it can be provided to the boiler.

2. When the boiler is in operation, ensure that the boiler water is at a normal water level to avoid excessively high boiler water level to reduce steam space, and then the phenomenon of steam with water.

3. If the steam boiler is in operation due to the large gas volume, the water-carrying phenomenon may be more serious. This may be due to the unreasonable design of the size of the air bag, the water level can be appropriately reduced, and the steam space can be increased to avoid the phenomenon of steam carrying water during operation.

If the steam boiler used in the food factory has serious water phenomenon, it may cause the boiler steam humidity to exceed the controllable range, which will cause inconvenience to users and affect the operating life of the boiler itself. Therefore, the steam boiler should be based on In the actual situation, corresponding measures shall be taken to avoid the occurrence of such phenomena and ensure the safe and efficient operation of the boiler.