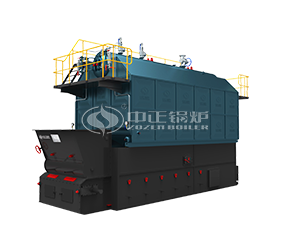

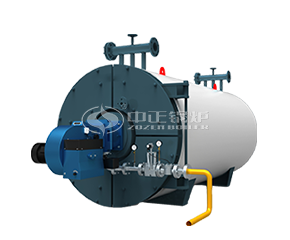

In the plastic foam industry, the continuous and efficient operation of production lines places high demands on boiler equipment. Boilers must not only ensure a stable heat supply but also meet environmental standards and optimize operating costs. Recently, Qinhuangdao Haishan Foam Co., Ltd. selected ZOZEN Boiler's newly launched DZW series reciprocating grate biomass boiler to provide robust support for its production needs.

The DZW series biomass boiler utilizes ZOZEN Boiler's fourth-generation technology, delivering an actual thermal efficiency that is 10% higher than that of standard biomass boilers. For plastic foam production companies, the operational stability of the boiler directly impacts the efficiency of the production line. The DZW series reciprocating grate biomass boiler features a high degree of automation, supporting automatic feeding, automatic soot blowing, and automatic ash removal. This not only reduces the need for manual operation but also effectively lowers the failure rate caused by improper manual handling.